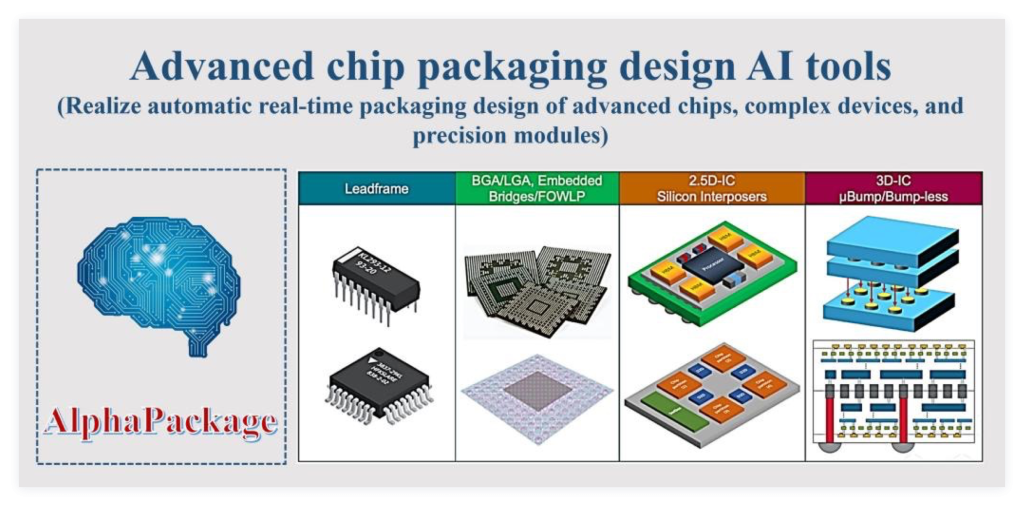

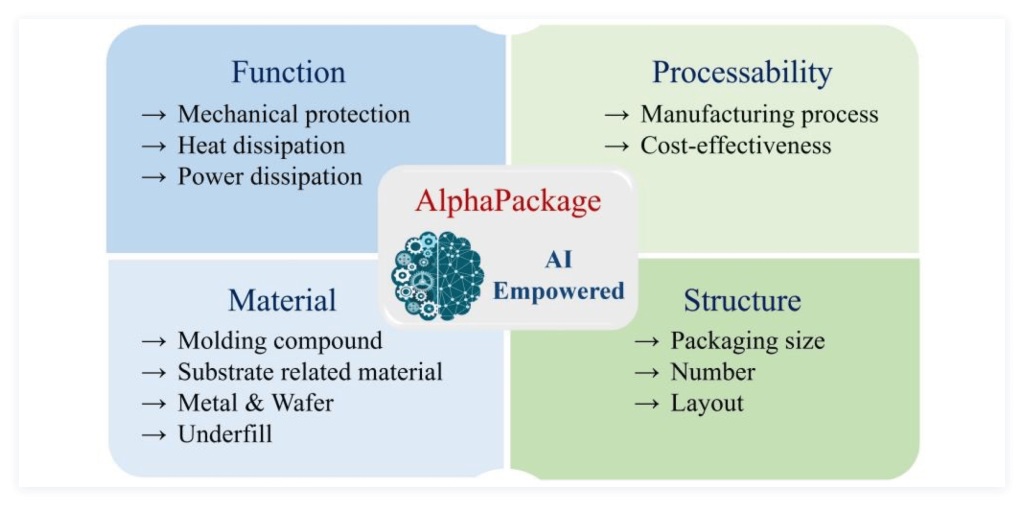

AI-assisted advanced chip packaging design

Project overview:

Advanced chip packaging technology is one of the important paths to improve system performance in the post-Moore's law era. It involves heterogeneous materials, structures, and high-density integrated devices, and has a large number of design variables under complex multi-physical field service environments, which poses a serious challenge to traditional chip packaging design ideas.

This project is based on my group's extensive theoretical knowledge, design experience, and rich data accumulated in chip packaging design. By utilizing the rapid development of artificial intelligence tools and computational capability, we aim to revolutionize the traditional chip packaging design methods and achieve a significant increase in the efficiency of packaging design optimization.

The main research content includes

1) Establish a sample database and design rules for advanced chip packaging based on multiphysics fields.

2) Building an interactive AI platform for chip packaging design based on the research in point 1.

3) Industrial application of AI-assisted advanced chip packaging design.

Design and manufacturing of nano-functional ceramic films

Project overview:

Vanadium redox flow batteries (VRFBs) is drawing increasing attention in large-scale energy storage applications nowadays. The membrane is a key component within VRFB cell that keeps the positive and negative electrolyte solution from mixing, thus allowing VRFB maintaining high efficiency over many cycles. Nafion, a perfluorinated sulfonic-acid ionomer, is one of the representative membrane applied in VRFB. However, the disadvantages of Nafion could not be neglected, such as high cost, short service life, severe vanadium ion permeability, etc. Thus, high performance inorganic composite membranes (ZHNM) are prepared from inorganic nanofiber membrane supports and the growth of ultra-thin zeolite membranes, in order to overcome the disadvantages of Nafion. The ZHNM have significantly improved the overall performance of VRFB, indicating that ZHNM is one of the most promising materials for VRFB in large-scale energy storage applications. This revolutionary technology helps to promote the efficient utilization of new energy and has huge strategic significance for ensuring national energy security and promoting sustainable economic and social development in our country.

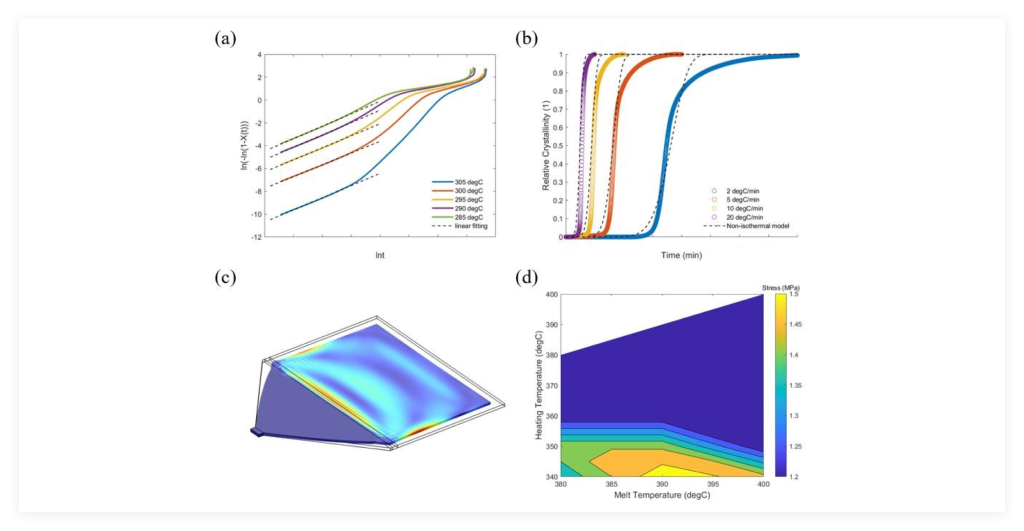

Design and optimization of high-performance polymer processing engineering with AI assistance

Project overview:

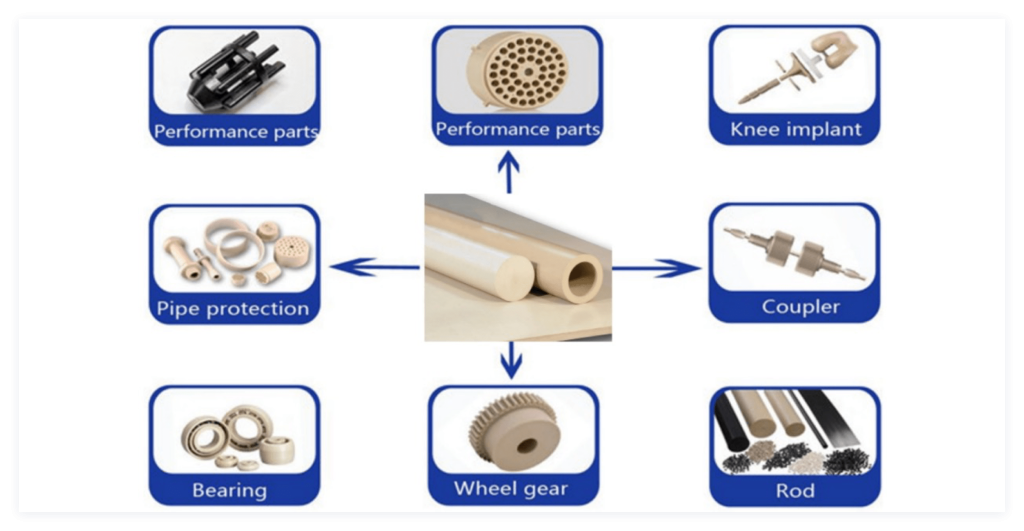

High-performance polymers, such as PEEK, have become increasingly important in various industrial applications due to their excellent mechanical, thermal, and chemical properties, which are widely used in aerospace, automotive, medical, and other industries.

Extrusion is a common processing method for high-performance polymers due to its efficiency and versatility. The extrusion process involves melting the polymer and forcing it through a die to create a continuous profile or filament of the desired shape and dimensions. The temperature, pressure, and shear rates during extrusion can greatly influence the final properties of the polymer product. However, extrusion is a complex process which involves many parameters, and the traditional trial and error method is not only time-consuming and material-wasting, but also may not result in good performance. Therefore, it is critical to introduce AI-enabling numerical methods to achieve desired properties with reduced time and cost.

In this project, a simulation method is established firstly for the PEEK extrusion process, which involves non-isothermal flow and crystallization, with the purpose of establishing a general relationship between process-structure-property and predicting the performance of the formed product. Furthermore, AI models are applied to design and optimize the processing parameters. Eventually, an interactive AI analysis model dedicated to high-performance polymer processing engineering will be developed, which will be a disruptive industrial design tool that facilitates industry professionals to quickly and efficiently design reasonable material formulations, obtain optimal process parameters, and produce qualified products.

Development and Application of the Intelligent Green Box System

Project overview:

GB-X(Green Box for Future) Laboratory is committed to researching and developing an Intelligent Green Box System. Based on innovative polymer environmentally friendly materials, the team independently developed a new generation green boxes that are lighter, more reliable, and offer a better user experience compared to traditional boxes. With the support of the intelligent reusing system of Internet of Things traceability technology, these new boxes promote the repeated use of packaging boxes. Faced with the increasingly urgent demand for sustainable development of logistics boxes in the logistics and transportation packaging industry, the laboratory team aims to reduce the cost of single packaging and improve the efficiency of packaging usage by reusing boxes more times. Also, the team sought to reduce the threat of ecological impact on the production, usage, and recycling of packaging materials by minimizing the number of boxes put into use.

Intelligent Green Box System can be divided into the following 4 sections, building up a complete technical chain of the whole process of the box "use-reuse":

1)Box Manufacturing: Produce and manufacture box materials and different specifications of boxes by developing intelligent manufacturing equipment through the exploration of box material processing technology.

2) Box Reusing: Enable the traceability of the box usage through the Internet of Things terminal equipment that uses high penetration, high directional RFID identification system as the core technology to research the box use and reusing process.

3) Box Packaging: Enhance the environmental friendliness and user experience during the whole process of box usage by using physical methods to compound the same materials, which replaces the use of traditional tape.

4) Digital System: Achieve digitized recycling of the packaging by attaching a tag chip to the box; Improve box reuse rates, reduce box loss rates, and optimize enterprises' production processes based on the data collected during the box recycling process.